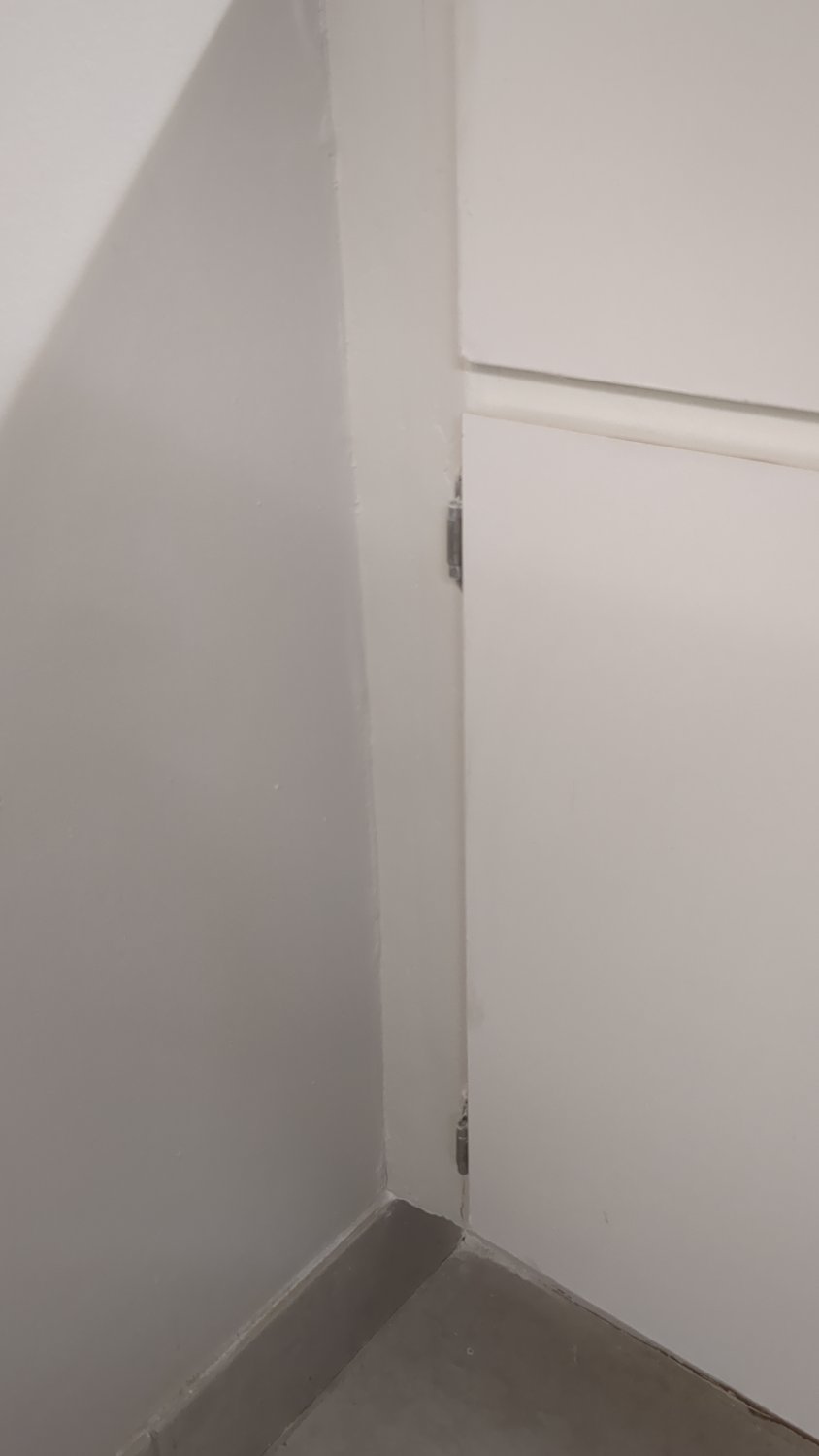

It’s a bit of a long story but someone tried using spray foam to fill the hole around where my sink’s plumbing goes through and it seems like it essentially expanded too much and causing the paint to tear.

I was thinking maybe I could get some rigid insulation cut it to size, stick it in there, and spackle over it followed by painting it. I would probably cut the rest of the paint to the top because it looks as if it is going to tear eventually and it’s at an angle.

Any suggestions?

The gap is close to an inch in size.

Someone linked the correct way but if you don’t have tools and just want to do a ‘landlord special’ for the time being you can fill the gap with foam backer rod (looks like foam rope, stuff it in), then caulk over it. Bowl of soapy water, dip finger in and use finger to make a nice bead. This is the landlord special mind you, it’s not a good permanent fix, just makes it look less ugly until you get around to tackling it, and costs about 12 bucks

This is what I ended up doing. I also used plaster to smooth things out. I think it ended up okay

Thanks for the tip

Acrylic and paint over. Or plaster.“Caulk and paint will make it what it ain’t”

Use some caulk saver foam, but this is a pretty easy DIY fix

“I’m not a great carpenter, I’m a great caulkender!”

Quote from a (carpenter) friend of mine

You fix the problem, not mask it.

Looks like the foam expanded and pushed the cabinet away from the wall.

Cut the foam back so the cabinet can rest where it belongs, and keep your friends away from spray foam.

Especially when there’s foam that is made to expand less, and sealers that don’t expand at all

If the gap is too large to caulk and your wall isn’t wavy against a straight edge, then you could use a color-matched piece of scribe molding. You’d probably want to use a nail gun, but more or less just make sure it will fit against the wall with enough room on the cabinet stile to attach (but not so wide that it hits the hinges). Once you’re ready to add the piece, cut it to length, run a line of glue where it will contact, then hold it snug against the wall and put a couple of brad/pin nails through it into the cabinet behind. Putty+touchup paint would be a good idea if you go this route.

If the wall isn’t straight then it might need to be cut to profile, which is more complicated but doable. You’d essentially need to make a proper scribe cut which may require a pencil and a saw. Of course, you could skip this and just apply the molding in combination with a very thin caulk line and then likely wouldn’t be able to tell it’s uneven (again, as long as the wall is reasonably straight)

Most hardware stores carry pre-finished scribe molding, and I’d highly recommend taking a door off its hinges to compare with the color selections available in store. Hell, if you pre-measure the exact width and length you need the molding to be ahead of time, many stores offer a service to get it pre-cut to size which helps things go as smoothly as possible. This is assuming you don’t have the tools on hand of course.

All that said, if you can fill the gap with a single bead of caulk running down the length, that’s almost guaranteed to be your best bet. Either way, you will almost certainly want to clean up the existing foam first.

I’d remove the foam causing the pressure because that may cause other problems, then I’d use the right type of expanding foam that fills cavities but does except much force, then I’d caulk the gap that is left.

Would it be fine to sparkle or caulk right up to the pipe that connects to my sink?

Quarter round trim Goulding. Easy peasy

The correct way

Nice 👍